IoT-Powered Digitization for Smart Industries

Trupti Panchal

Understanding IoT and Its Impact on Industry 4.0

What is IoT?

Importance of IoT

Why IoT is Crucial for Industry 4.0

The rise of Industry 4.0 is heavily reliant on IoT technologies, which enable smarter factories and connected production lines. Here are several ways IoT is transforming the manufacturing process:

- Real-Time Monitoring: IoT devices provide manufacturers with real-time data, allowing for better oversight and decision-making.

- Predictive Maintenance: IoT sensors monitor machine health, sending alerts when maintenance is required. This reduces downtime and prevents costly repairs.

- Automation and Efficiency: IoT enables systems to automate routine processes, improving productivity and reducing human error.

- Enhanced Communication and Collaboration: IoT facilitates seamless communication between machines, workers, and systems, improving coordination across the supply chain.

IoT Applications developed by Techpearl

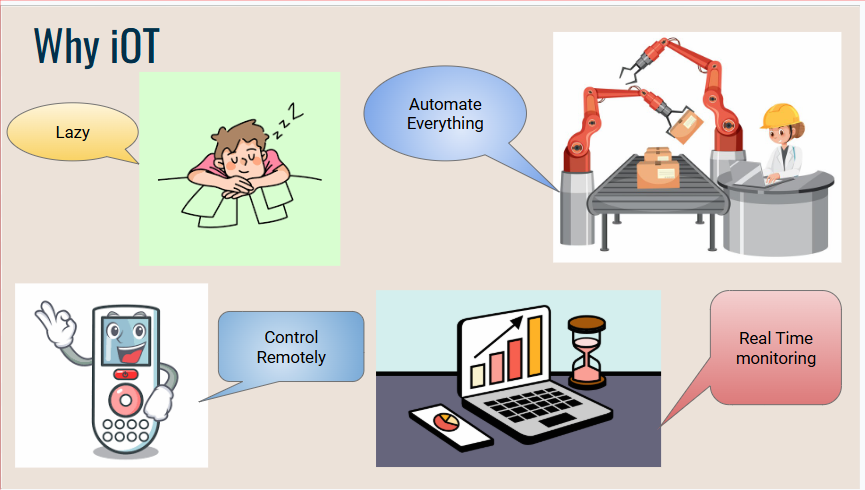

1. Proactive Industrial Maintenance Tracker App

This module combines preventive maintenance with real-time sensor data, providing insights into machine health and triggering alerts when maintenance is due. By detecting issues early and optimizing maintenance schedules, it helps prevent unexpected failures, lowers repair costs, and minimizes downtime.

Objective:

Optimize asset management through effective scheduling and oversight of maintenance activities, including preventive maintenance, breakdown management, and calibration tool management.

Key Features:

- Asset Management

- Preventive Maintenance Management

- Breakdown Management

- Calibration Tool Management

- Calibration Maintenance

- Reports

Value & Benefits:

IoT sensors enable manufacturers to monitor machine health and performance in real-time. By tracking machine usage and condition, manufacturers can predict potential failures before they occur, optimize machine utilization, and reduce downtime. Additionally, IoT facilitates predictive maintenance, replacing time-based schedules with data-driven insights, ensuring that maintenance is performed only when necessary. This approach extends the lifespan of equipment and reduces unnecessary service calls, significantly cutting maintenance costs.

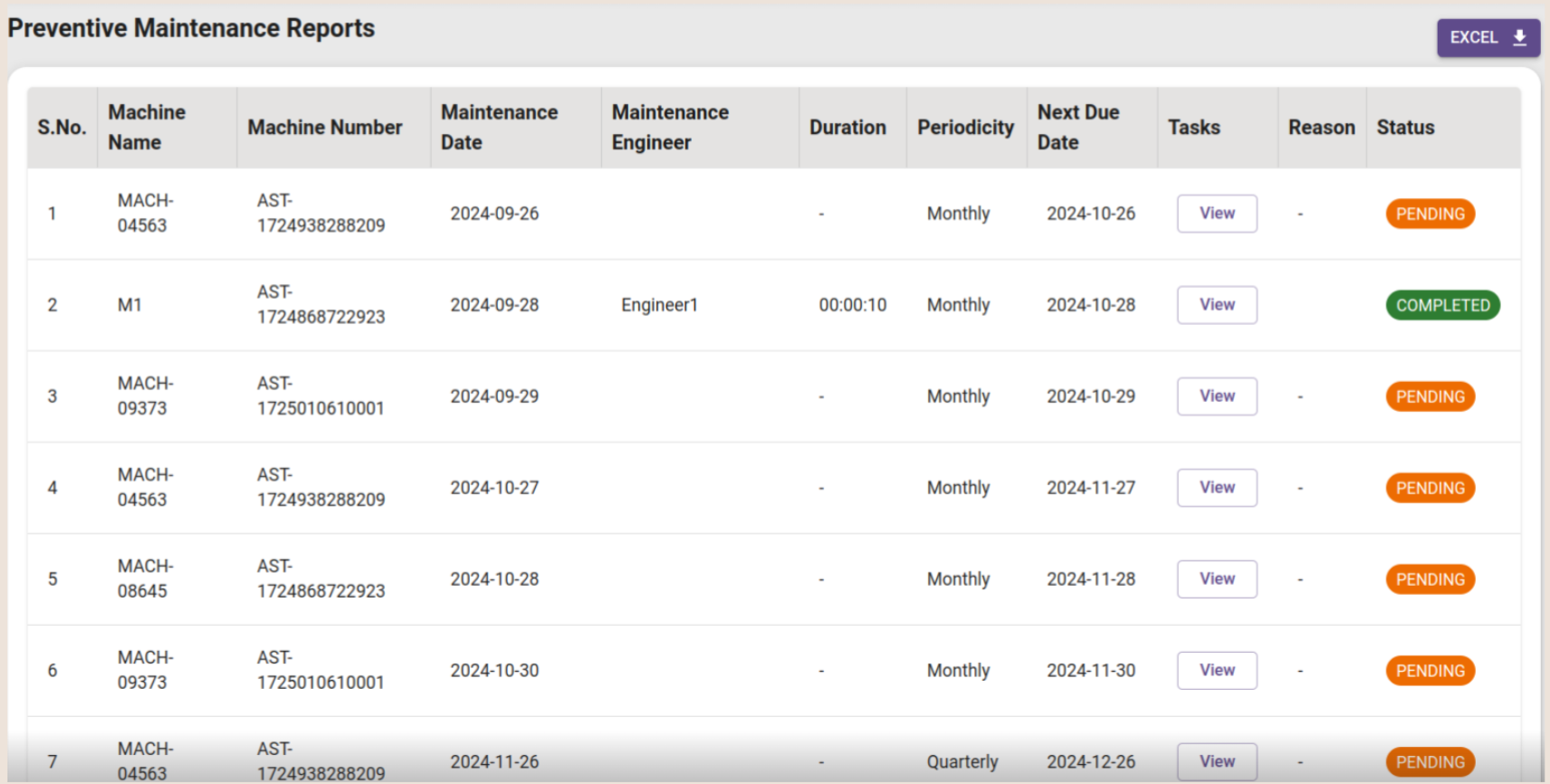

2. Tool Lifecycle Tracker App

This module tracks the lifecycle of tools and critical assets, ensuring they are replaced on time and used efficiently. Continuous monitoring minimizes downtime, optimizes asset utilization, and ensures better management throughout the lifecycle.

Objective:

Track the life of each tool in the manufacturing machines, monitor tools for better inventory planning, and improve tool lifecycle management.

Key Features:

- Tool Dashboard

- Tool Consumption

- Critical Tool Life

- Dashboard (Card View and Tabular View)

- Lifecycle Tracking Of Each Tool

Value & Benefits:

With IoT, manufacturers gain real-time visibility into asset location, usage, and condition. This improves asset utilization, enhances lifecycle management, and reduces the risk of asset loss or theft.

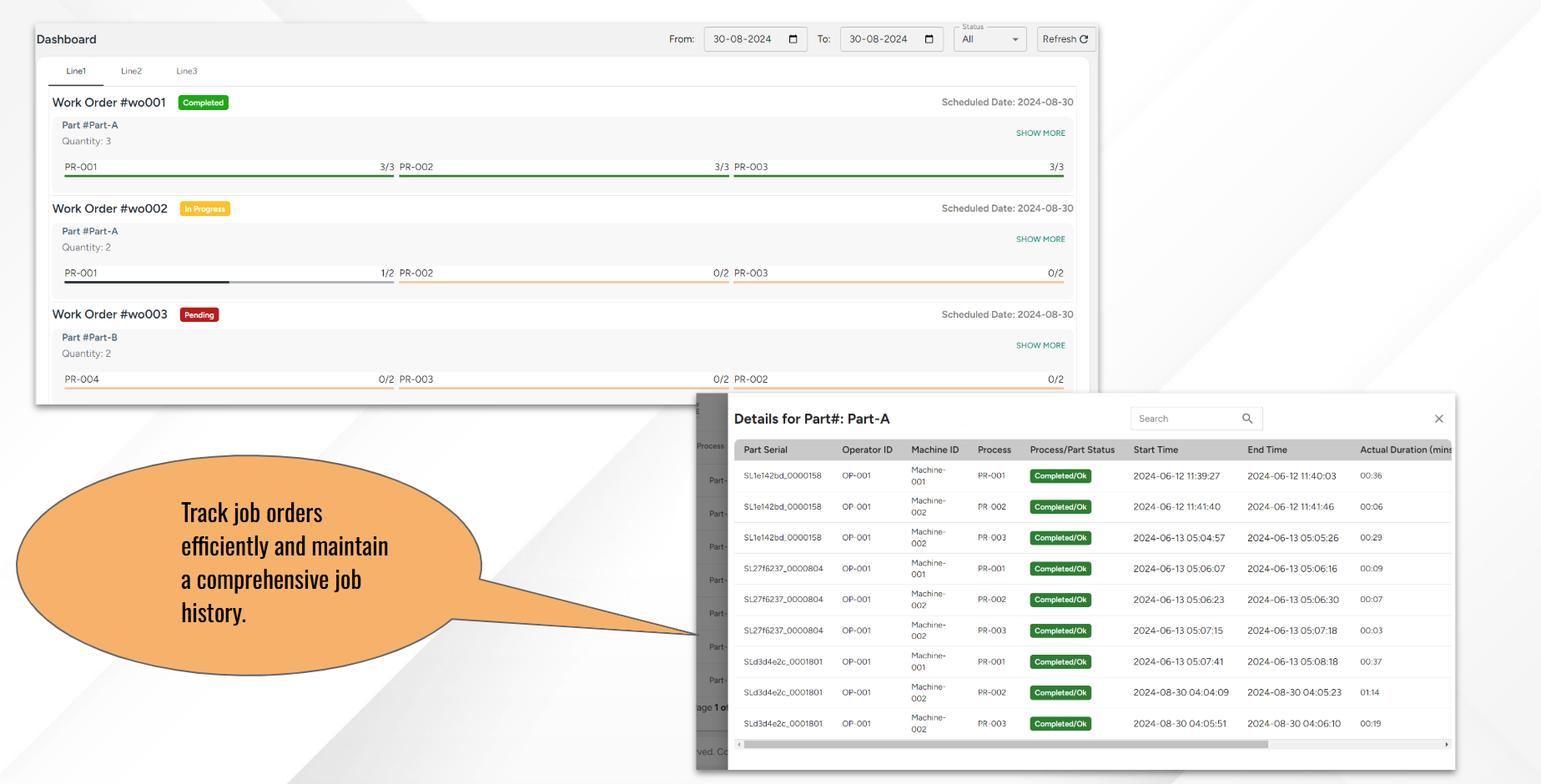

3. Job Order Tracker and Validation App

This App tracks each part’s journey through production, ensuring accurate asset management and traceability. It validates each part at every stage, improving inventory control and reducing errors.

Objective:

Track job orders efficiently, maintain a comprehensive job history, and provide part tracing in case of manufacturing defects.

Key Features:

- Work Order Sequencing

- Machine Settings

- Job Sequence & Validation

- Data Recording

- Trace Part

- Report Generation

Value & Benefits:

IoT enables real-time tracking of assets throughout the entire supply chain, from raw materials to finished products. This enhances inventory management, ensures timely material delivery, and improves traceability and transparency.

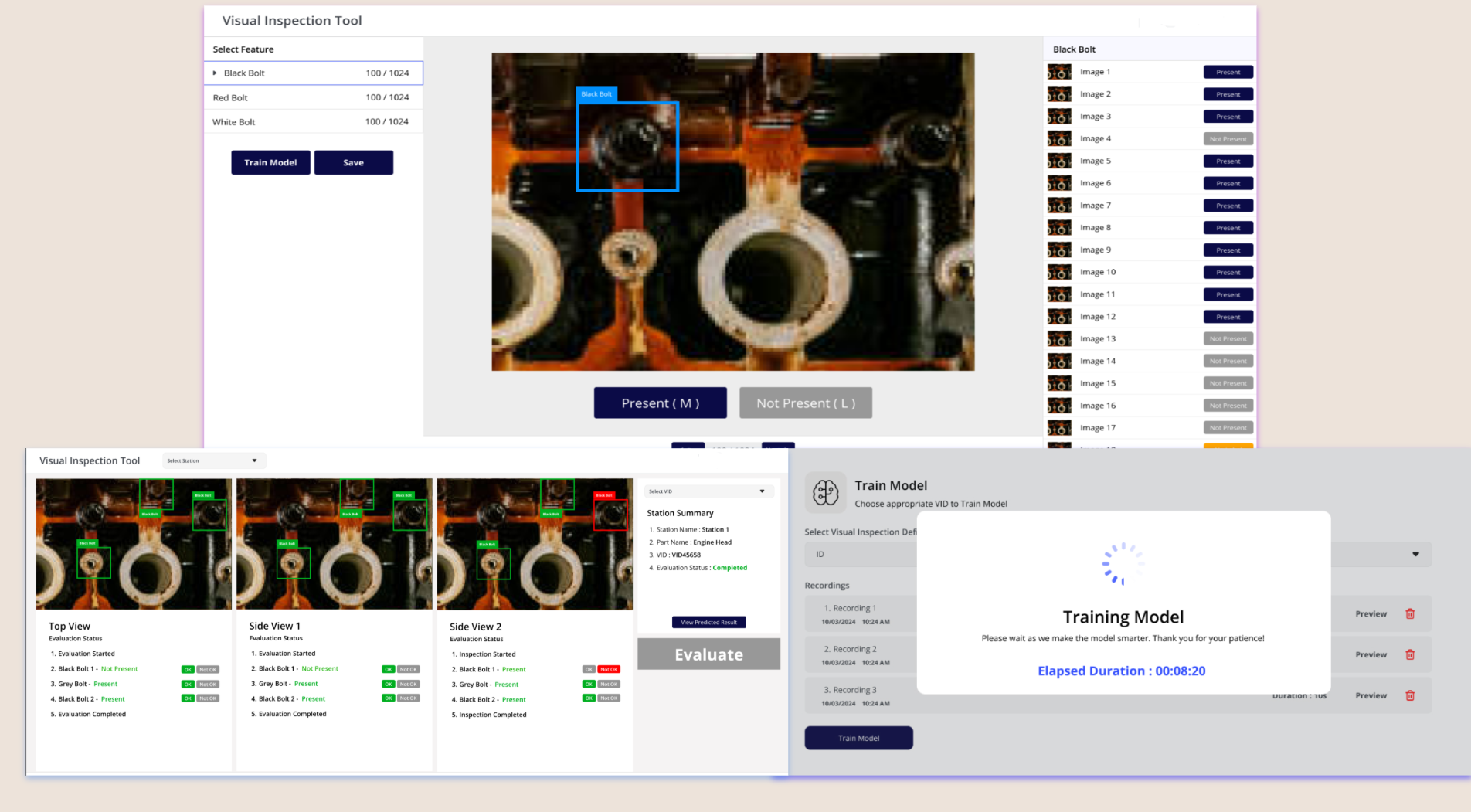

4. AI-Powered Automated Defect Detection Engine

Objective:

Automate visual inspection for product defects using AI applications.

Key Features:

- Managing Stations

- Defining Inspections

- Collecting Data

- Labeling Data

- Training the Model

- Evaluating & Inspecting

Value & Benefits:

IoT enhances real-time quality control by monitoring production processes and detecting deviations from predefined standards. This ensures issues are addressed immediately, improving overall product quality and customer satisfaction.

5. Digital Rights Management App

This robust App controls access to software features, ensures compliance with licensing agreements, and protects intellectual property through secure user management.

Objective:

Manage user access by issuing and validating licenses for software use, ensuring compliance and controlling feature availability based on the license type.

Key Features:

- License at Module Level

- License for Online and Offline (On-Premise) Modules

- License Encryption

- Early Warning of Expiry

- Request for New/Renewed License

Benefit:

Manufacturers often rely on software solutions, and ensuring compliance with licensing agreements and protecting intellectual property is critical. Digital rights management (DRM) helps safeguard these assets.

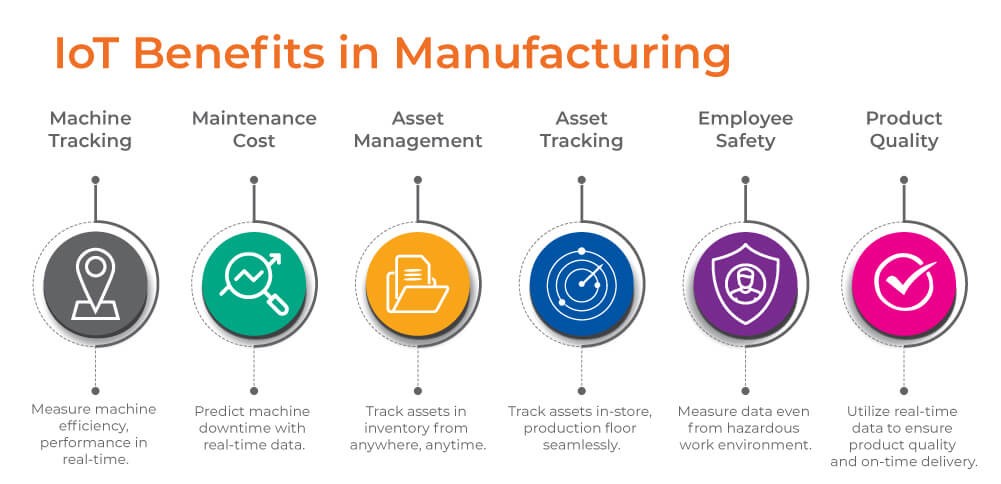

The below illustration summarizes the diverse benefits derived from the applications developed by Techpearl.

Conclusion

The integration of IoT into manufacturing has transformed traditional processes, enabling real-time monitoring, predictive maintenance, and automation. This shift addresses key challenges like downtime, inefficiencies, and lack of traceability, improving productivity and decision-making.

Techpearl’s IoT solutions demonstrate these benefits through applications such as the Proactive Maintenance Tracker, which reduces downtime, and the Tool Lifecycle Tracker, which improves asset utilization. Other solutions, like the Job Order Tracker and AI-Powered Defect Detection, enhance traceability and product quality. Digital Rights Management ensures software compliance and protects intellectual property.

By adopting IoT-driven solutions, manufacturers can streamline operations, reduce costs, and stay competitive. IoT empowers businesses to build smarter, more connected, and efficient manufacturing ecosystems, driving sustainable growth in the era of Industry 4.0.