Kripya – IoT Driven Smart Industry Solutions

Category

IoT Software Platform

Location

India

Engagement

Since 2023

Services

Full Stack App Development

01

Overview

The project focuses on the development and deployment of IoT-driven Industry 4.0 solutions designed to enable real-time monitoring, generate data-driven insights, and digitize shop floor operations for maximum productivity.

Delivered as a SaaS-based Industry 4.0 platform, it caters to sectors such as Manufacturing, Energy, Telecom, Retail, and more.

The platform enhances operational visibility, streamlines process monitoring, and provides customized applications to transform shop floor activities, driving efficiency and innovation.

02

Business Challenge

The current monitoring and management mechanisms for manufacturing processes in most small and medium-sized enterprises are predominantly manual

Extended cycle times are required to identify and address production issues, including downtimes caused by machinery failures, employee skill gaps, and other inefficiencies.

Plant supervisors struggle to obtain a consolidated view of actual versus planned production, making it difficult to pinpoint bottlenecks and inefficiencies.

Senior management faces challenges in gaining a comprehensive overview of production quality, productivity levels, workforce skills, and insights necessary for strategic planning, including expansion, budgeting, and maintenance activities.

Cross-departmental dependency resolution is time-consuming, delaying operational decisions and problem resolution.

A lack of traceability for past production issues hampers root cause analysis and continuous improvement efforts.

03

Business Solution Overview

Key IoT Applications in Industry 4.0: Developed by Techpearl

Proactive Industrial Maintenance Tracker App

This App combines preventive maintenance with real-time sensor data, providing insights into machine health and triggering alerts when maintenance is due. By detecting issues early and optimizing maintenance schedules, it helps prevent unexpected failures, lowers repair costs, and minimizes downtime.

Tool Lifecycle Tracker App

This module tracks the lifecycle of tools and critical assets, ensuring they are replaced on time and used efficiently. Continuous monitoring minimizes downtime, optimizes asset utilization, and ensures better management throughout the lifecycle.

Job Order Tracker and Validation App

This App tracks each part’s journey through production, ensuring accurate asset management and traceability. It validates each part at every stage, improving inventory control and reducing errors

AI-Powered Automated Defect Detection Engine

Leveraging AI and IoT sensors, this module automates defect detection during production. It ensures consistent product quality, reduces manual inspections, and boosts overall production efficiency.

Digital Rights Management App

This robust App controls access to software features, ensures compliance with licensing agreements, and protects intellectual property through secure user management.

04

Proactive Industrial Maintenance Tracker App

04

Proactive Industrial

Maintenance Tracker App

Objective

- Optimize asset management through effective scheduling and oversight of maintenance activities, including preventive maintenance, breakdown management, and calibration tool management.

Key Features

- Asset Management

- Preventive Maintenance Management

- Breakdown Management

- Calibration Tool Management

- Calibration Maintenance

- Reports

Value & Benefits

- IoT sensors enable manufacturers to monitor machine health and performance in real-time. By tracking machine usage and condition, manufacturers can predict potential failures before they occur, optimize machine utilization, and reduce downtime. Additionally, IoT facilitates predictive maintenance, replacing time-based schedules with data-driven insights, ensuring that maintenance is performed only when necessary. This approach extends the lifespan of equipment and reduces unnecessary service calls, significantly cutting maintenance costs.

05

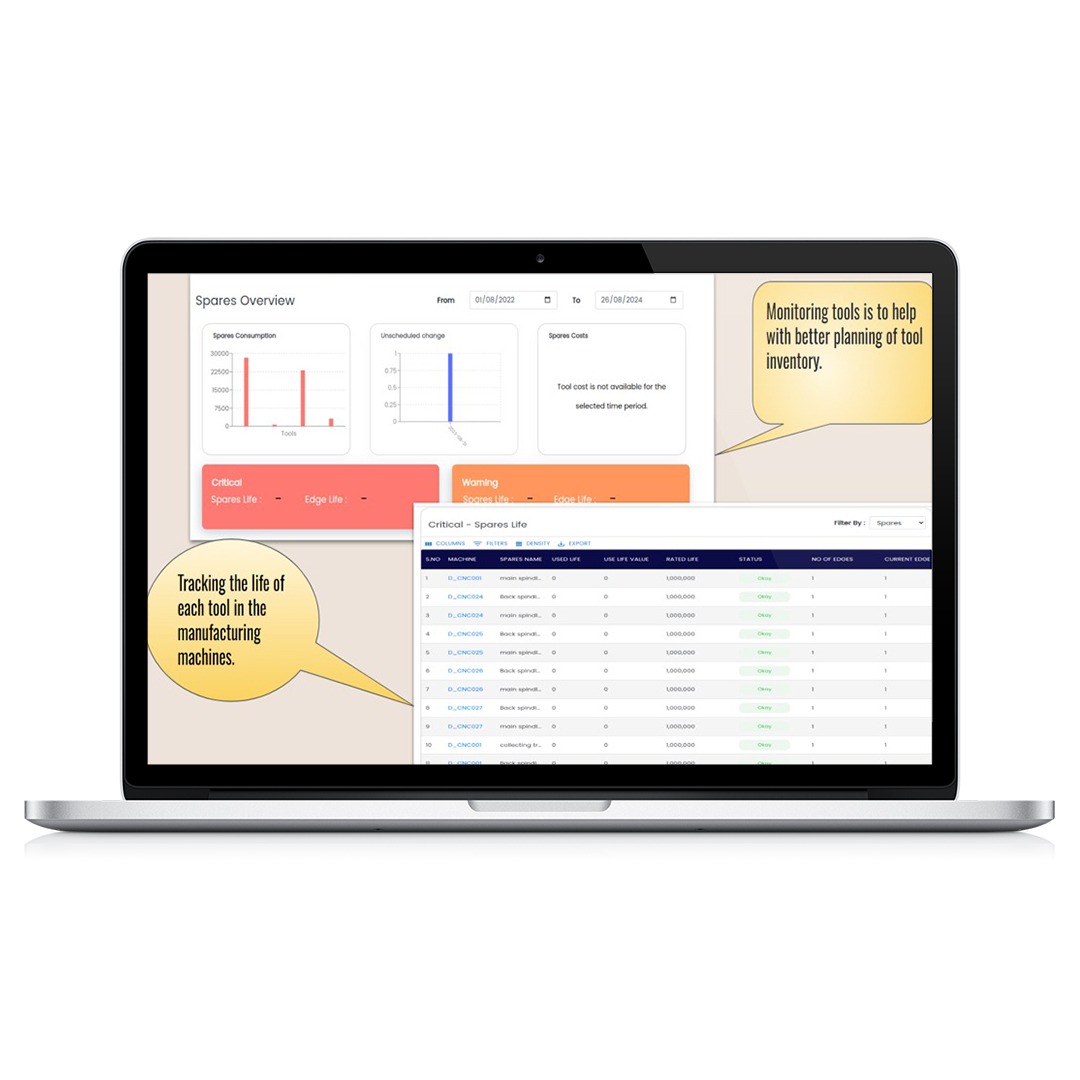

Tool Lifecycle Tracker App

Objective

- Track the life of each tool in the manufacturing machines, monitor tools for better inventory planning, and improve tool lifecycle management.

Key Features

- Tool Dashboard

- Tool Consumption

- Critical Tool Life

- Dashboard (Card View and Tabular View)

- Lifecycle Tracking Of Each Tool

Value & Benefits

- With IoT, manufacturers gain real-time visibility into asset location, usage, and condition. This improves asset utilization, enhances lifecycle management, and reduces the risk of asset loss or theft.

06

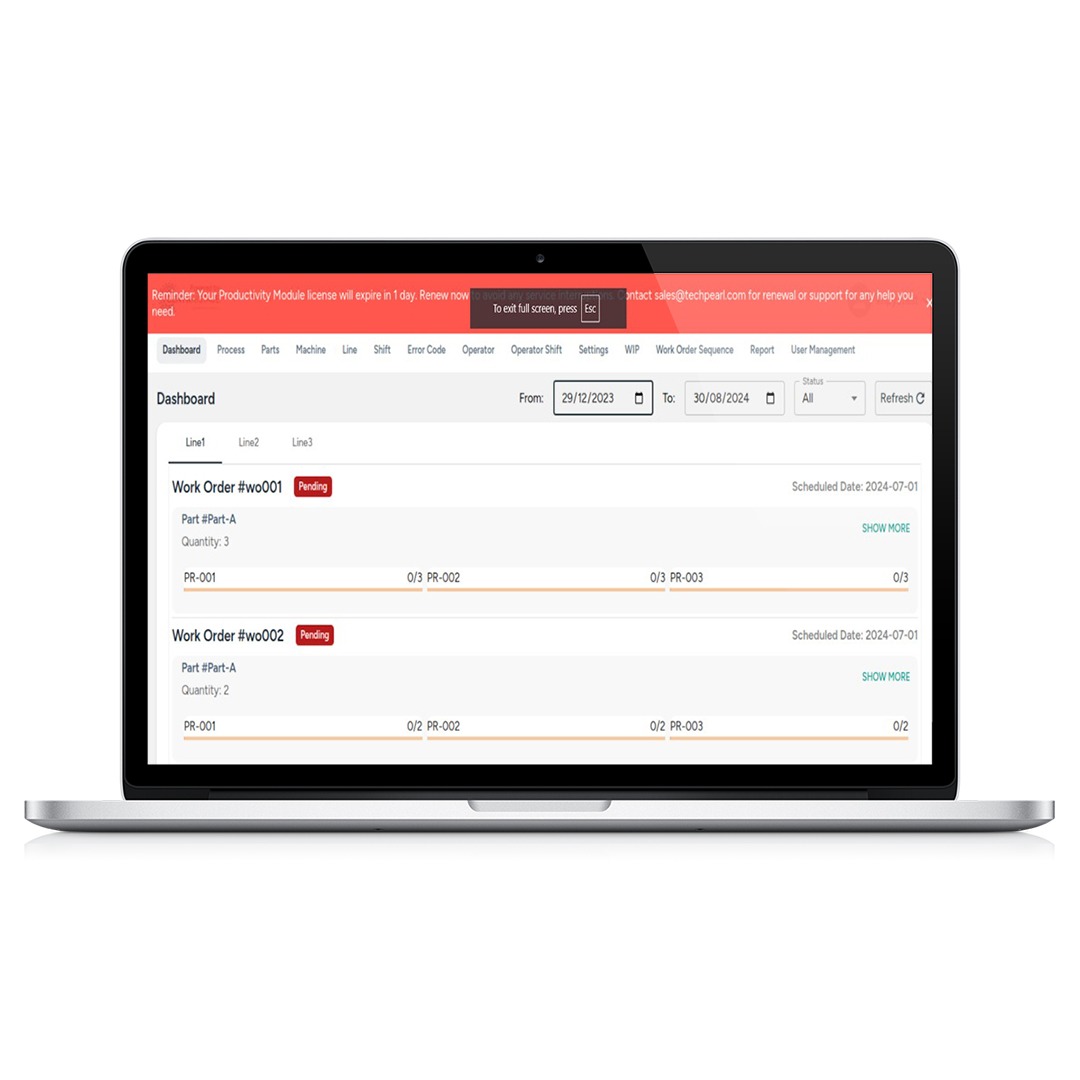

Job Order Tracker & Validation App

Objective

- Track job orders efficiently, maintain a comprehensive job history, and provide part tracing in case of manufacturing defects.

Key Features

- Work Order Sequencing

- Machine Settings

- Job Sequence & Validation

- Data Recording

- Trace Part

- Report Generation

Value & Benefits

- IoT enables real-time tracking of assets throughout the entire supply chain, from raw materials to finished products. This enhances inventory management, ensures timely material delivery, and improves traceability and transparency.

07

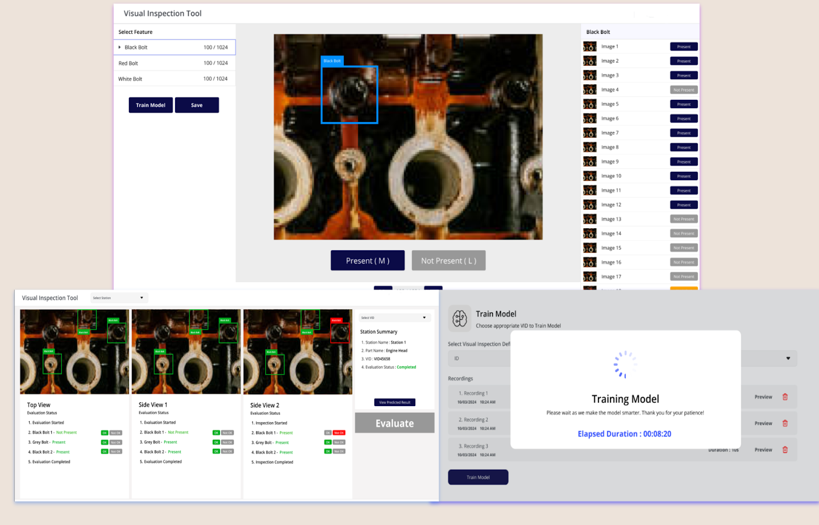

AI-Powered Automated Defect Detection Engine

07

AI-Powered Automated Defect

Detection Engine

Objective

- Automate visual inspection for product defects using AI applications.

Key Features

- Managing Stations

- Defining Inspections

- Collecting Data

- Labeling Data

- Training the Model

- Evaluating & Inspection

Value & Benefits

- IoT enhances real-time quality control by monitoring production processes and detecting deviations from predefined standards. This ensures issues are addressed immediately, improving overall product quality and customer satisfaction.

08

Digital Rights Management App

Objective

- Manage user access by issuing and validating licenses for software use, ensuring compliance and controlling feature availability based on the license type.

Key Features

- License at Module Level

- License for Online and Offline (On-Premise) Modules

- License Encryption

- Early Warning of Expiry

- Request for New/Renewed License

Value & Benefits

- Manufacturers often rely on software solutions, and ensuring compliance with licensing agreements and protecting intellectual property is critical. Digital rights management (DRM) helps safeguard these assets.

09

Technologies Used

10

Values & Benefits

UNISON is a music application that caters to the needs of bands and their directors. It provides the convenience of paperless solutions, eliminating the inconvenience of printing. UNISON allows users to create a digital library of their music files from their computer and effortlessly distribute them to their students in the program. The app also offers seamless updates to shared files, ensuring that any modifications made to the library are instantly reflected within the UNISON application.

SWAE is an all-in-one decision making and governance tool empowering the next generation of Web3 DAO(Decentralized Autonomous Organization) communities. Techpearl continues to work as the technology partner to Swae since 2017 and handles the end to end product development covering deployment of engineering processes & tools. AWS serverless architecture was adopted to provide a cost effective solution.